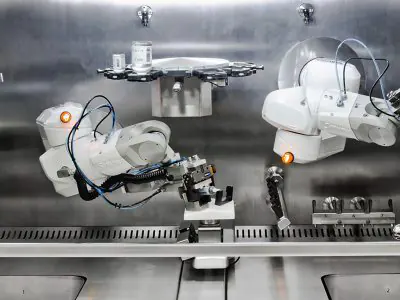

KIRO ONCOLOGY Robotic Drug Preparation System

GRIFOLS

Robotic Drug Preparation System for Sterile Preparation of Harmful Drugs

Robotic Drug Preparation System for Sterile Preparation of Harmful Drugs. Precision scales for gravimetric verification at all stages of the preparation process to control dosing accuracy. During the process, barcode readers and cameras identify drugs, disposables and end containers to document traceability

Joining Area

- Two robotic arms,

- 12 position rotating stand for bottles in use. (1-100 mL),

- Preparation chamber for up to 8 infusion bags, cassettes or elastomeric pumps,

- Syringe holder for up to 8 syringes (1, 3, 10, 20 and 50 mL),

- Syringe closing station with 4 cap positions,

- Partially used holding area for 10 bottles,

- Gravimetric device for weighing during operation,

- Two peristaltic pumps for diluent filling of empty containers and reconstitution of lyophilized medicine bottles,

- Two cameras for syringe and vial identification, respectively,

- Barcode reader for product identification.

User Interface Area

- User touch screen interface,

- Gravimetric device to double-check weighing,

- Barcode reader for product identification,

- Two label printers (small and large labels).

Clean Air Area

- ISO 5 preparation area,

- Environmental protection and negative pressure control in circulation and discharge with HEPA discharge filter,

- User protection with closed preparation environment under negative pressure,

- 30% discharge and 100% discharge options are available.

Waste Area

- Two self-enclosed waste disposal units to avoid user exposure,

- Two additional Bag-In Bag-Out filters for air purification before recirculation.

Patient Safety

- Precise scales for gravimetric verification at all stages of the preparation process to control dosing accuracy,

- During the process, barcode readers and cameras identify drugs, disposables and end containers to document traceability.

Personnel Protection

- Self-cleaning action avoids manual cleaning,

- Automatic priming and self-cleaning takes place in a completely enclosed environment,

- Integrated system for automatic disposal of hazardous wastes into independent bags,

- Operators are protected from repetitive stress injuries.

Flexibility and Efficiency

- Supports a wide variety of bottles and end containers,

- Prepares patient-specific doses and small batches using liquid or lyophilized drugs,

- Improved device and user productivity by allowing user identification and labeling of materials during automated preparation,

- Software-guided combination, replacement and reuse of vials for optimal drug use, including partially used vial tracking and labeling,

- Workflow optimized by visual planning dashboard,

- Configuration options to respond to specific preparation practices, workflows and clinical needs.

Regulatory Compliance

Compliance with supported USP and GMP regulations by standardizing aseptic procedures, facilitating personnel and process qualification, and minimizing exposure when preparing hazardous drugs.

Airflow operation and temperature control and optional continuous particle counter to meet GMP requirements.

Fully maintained during deployment, qualification, and periodic maintenance, including dosing accuracy tests and airflow certifications addressing smoke tests under dynamic conditions for USP compliance.

Syringes can be automatically sealed with infusion bags and CSTDs loaded with a pre-attached CSTD spike to feed sealed containers and meet USP requirements for the administration of hazardous drugs.

KIRO Oncology meets electrical safety requirements with UL listing marked according to IEC 61010 and EMC certification according to IEC 61326-1.

Hi!

May i help you?

08:27